Added weight of Wood Sealant

November 2005 Saskatoon, Canada

Seal-It International Inc. was recently asked a question that we could not answer. No one at Seal-It could remember a customer, or distributor, asking this question before. When a Colorado distributor of Seal-It products was asked to help reduce maintenance costs for a wooden treaded, pedestrian suspension bridge; the question of added weight had to be answered. Seal-It contracted the services of Enviro-Test Laboratories, a division of CHEMSPEC ANALYTICAL LIMITED, to determine the weight added when Seal-It Wood Sealant is applied.

Two different sized pieces of “raw” wood (non pressure treated), cut from the same dimensional piece of fir lumber, were weighed. The smaller piece labeled SIW 1 weighed 53.1165 grams; the larger, SIW 2 weighed 699.7 grams before Wood Sealant was applied.

Seal-It Wood Sealant was applied to these pieces of wood following Seal-its instructions. The samples were allowed to cure and dry for two days, after which they were weighed again by Enviro-Test Laboratories.

Wood sample SIW 1 now weighed 53.5502 grams, an increase of only 0.8165%. Sample SIW 2 now weighed 703.7 grams, an increase of 0.5717%. That works out to about 1.5 lbs per ton of wood treated.

Seal-It, its customers and distributors feel this is a small “burden to bare” to get the added “rot” and wear resistance that Seal-It Wood Sealant will add to your wood structures and projects.

This document is also available in PDF format

Flame Spread and Wood Sealant

Prevent Rot

At Seal-It, we knew our wood sealant prevented rot. We were told the wood sealant would prevent rot, we believed what we were told. Our customers told us it prevented rot, and of course, we have seen for ourselves, Seal-It Wood Sealant prevents wood rot.

But, unlike Seal-It Concrete Sealant, our Wood Sealant had fewer reported laboratory tests that confirmed its capabilities.

We also knew, and believed, that the best place to invest profits was back into the business that generated the profit. In the past this belief led to investment in advertising, both print and internet. With less than profitable results, actually less than breakeven results, we were disillusioned about advertising.

Although, still believing in the principle of re-investment in your own business, we decided to enhance the value of one of our hottest selling products, Seal-It Wood Sealant. Could it be proven scientifically that our wood sealant prevented rot?

Now to find a business that could prove Seal-It Wood Sealant would prevent wood rot, scientifically! This seemed to prove more difficult than we thought it should have, searching the internet provided sparse results. But the search did provide results. Lakehead University, Thunder Bay, Ontario, Canada could do what we were looking for. This made sense, Thunder Bay, Ontario, in the heart of lumber country!

We talked to Dr. Mathew Leitch, Professor of wood science. He and his associate presented Seal-It with a plan to prove Seal-It Wood Sealant’s ability to prevent wood rot.

This, below, is the text from email received from Dr. Leitch:

“I have talked it over with the other Prof who will work on this and we have come up with a plan. The process of testing this according to standards is to place the blocks as I mentioned into a media that has white and brown rot fungi (separate for each type of fungi). The standards recommend testing of several boards. So we see testing 10 to 20 cubes in each fungi type and a similar number for controls in order to compare the mass loss.”

So, in our words, Seal-It would provide Professor Leitch with pine wood cubes, some treated with Seal-It Wood Sealant, and some not. We took pine lumber, fresh from the lumber yard, and cut 150 cubes ¾” x ¾” x ¾”. 100 of these cubes were treated with Seal-It Wood Sealant, and 50 left untreated. The cubes were individually identified and placed in sealed containers for delivery to Lakehead University. 100 treated cubes in one container, 50 untreated cubes in another container. Each container, as clearly as possible, identified as to its contents; “Treated with Seal-It Wood Sealant”, and “Not Treated”.

From here on, we are told the blocks of wood will be placed in controlled environment containers. One of four types of fungus placed in these containers with the wood.

According to the internet, these fungi are responsible for wood rot.

The lab received the wood cubes mid December 2016, and Seal-It received test results in Late July 2017 with this quote from Dr. Leitch: “Please find the results for the durability tests we did for you.”, “It appears the solution you have is pretty effective.”

We were quite pleased with that quote coming from a person that signs his name:

Dr. Mathew Leitch, HBScF Chair

Associate Professor

Faculty of Natural Resources Management

Wood Science and Forest Products

Director, Lakehead University Wood Science and Testing Facility.

At the end of about 7 months, with wood cubes and fungus in containers that had been temperature and humidity controlled for optimum growth conditions of the fungus, the containers were opened.

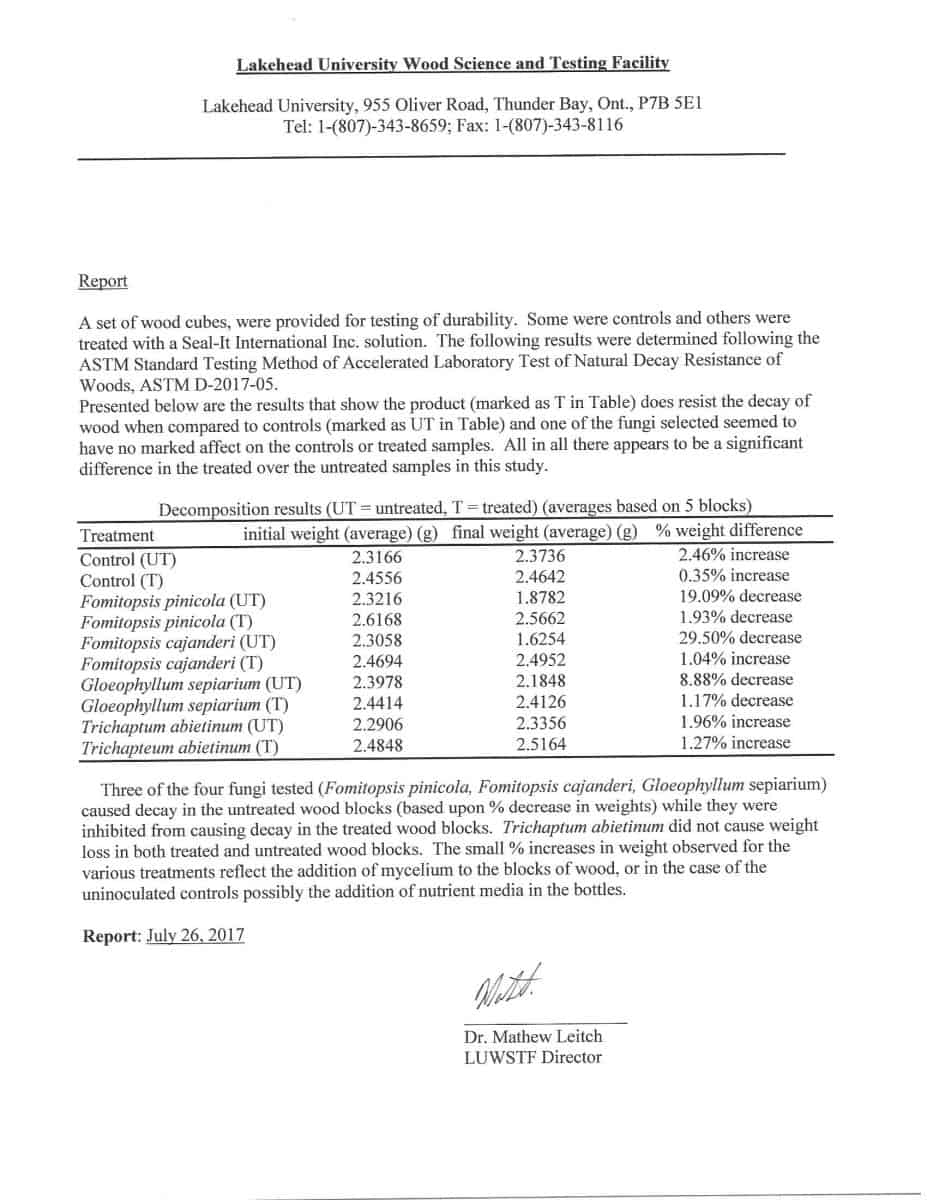

Each cube would be weighed with the expectation that rot would have removed material from the wood. Less weight means more rot activity. The results of testing are in the table below.

“Control” designates wood cubes placed in humidity and temperature controlled containers with “no” rot fungus added. Some of the cubes had been “untreated” (UT) with Seal-It Wood Sealant, and some cubes had been “treated” (T) with Seal-It Wood Sealant.

So why did these cubes gain weight? Dr. Leitch addresses this and explains the increase in weight probably due to the addition of nutrients for the fungus, and the fungus itself.

Further on in the results table we see that there are both treated and untreated wood cubes exposed to each of four types of rot fungus. Three of the four fungus show from 8+% to 29.5% weight loss for wood cubes untreated with Seal-It Wood Sealant. And for wood cubes sealed with Seal-It Wood Sealant, from just under 2% loss of weight to just over 1% increase in weight.

So, to quote Professor Leitch’s: “All in all there appears to be a significant difference in the treated over the untreated samples in this study.”

Decomposition results (UT = untreated, T = treated) (averages based on 5 blocks)

| Treatment | Initial weight (average) (g) | Final weight (average) (g) | % weight differance |

|---|---|---|---|

| Control (UT) | 2.3166 | 2.3736 | 2.46% increase |

| Control (T) | 2.4556 | 2.4642 | 0.35% increase |

| Fomitopsis pinicola (UT) | 2.3216 | 1.8782 | 19.09% decrease |

| Fomitopsis pinicola (T) | 2.6168 | 2.5662 | 1.93% decrease |

| Fomitopsis cajanderi (UT) | 2.3058 | 1.6254 | 29.50% decrease |

| Fomitopsis cajanderi (T) | 2.4694 | 2.4952 | 1.04% increase |

| Gloeophyllum sepiarium (UT) | 2.3978 | 2.1848 | 8.88% decrease |

| Gloeophyllum sepiarium (T) | 2.4414 | 2.4126 | 1.17% decrease |

| Trichaptum abietinum (UT) | 2.2906 | 2.3356 | 1.96% increase |

| Trichaptum abietinum (T) | 2.4848 | 2.5164 | 1.27% increase |